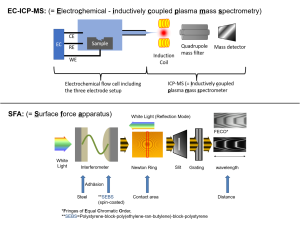

The goal of various industrial projects in our group is to obtain fundamental knowledge about oxide layer properties, corrosion and passivation processes of steal samples. Various methods are used for characterization, such as electrochemistry (EC), inductively coupled plasma mass spectrometry (ICP-MS), x-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM), surface force apparatus (SFA) and confocal microscopy. Firstly, coupling of an electrochemical flow cell and an ICP-MS makes it possible to imitate corrosion and passivation within the electrochemical flow cell. The dissolved material can then be transported directly into the ICP-MS where the ratio of dissolved elements can be analyzed. An adaption that allows for in-situ scratching gives an even deeper insight into the processes. Secondly, adhesive interaction of a polymer with the surface of differently treated steel samples is of interest. These samples were oxidized, either with plasma or thermally. This treatment influences the oxide layer of the steel sample, which in turn has an influence on the adhesive properties of the steel. This adhesive interaction was analyzed by utilizing the SFA.